The Factories Act, 1948: A Comprehensive Guide to Worker Safety, Health, and Welfare in India

This definitive guide to the Indian Factories Act, 1948, details the essential labour laws governing worker health, safety, and welfare, while covering compliance, working hours, and the critical transition to the new OSH Code, 2020.

A cornerstone of India’s labour law framework, the Factories Act of 1948 stands as a testament to the nation’s commitment to protecting its industrial workforce. Enacted shortly after independence, this pivotal legislation consolidates and amends the laws regulating labour in factories, establishing a comprehensive regime for the health, safety, welfare, and working conditions of millions of workers. This article delves deep into the provisions of the Factories Act, 1948, its judicial interpretations, its evolution, and its continuing relevance in the 21st century, providing a vital resource for employers, employees, and legal practitioners alike.

Introduction: The Genesis and Objectives of the Factories Act, 1948

The Indian Factories Act, 1948, was born out of a long history of industrial exploitation and a growing recognition of the need to humanize working conditions. The industrial revolution in India, much like in other parts of the world, brought with it deplorable working environments, excessive hours, and a blatant disregard for the well-being of labourers. Early factory legislation in India, starting from 1881, was piecemeal and inadequate. The 1948 Act, however, marked a paradigm shift. It was a comprehensive piece of social legislation that aimed to provide a safe and healthy working environment, promote the welfare of workers, and regulate their working hours.

The primary objectives of the Factories Act, 1948, are:

- To ensure the health of workers by prescribing standards for cleanliness, ventilation, temperature, and the disposal of wastes and effluents.

- To guarantee the safety of workers by mandating the fencing of machinery, prescribing safe working practices, and laying down protocols for hazardous processes.

- To promote the welfare of workers by requiring the provision of amenities such as washing facilities, canteens, crèches, and first-aid.

- To regulate the working hours of adults, women, and young persons to prevent over-exploitation and ensure adequate rest.

- To provide for the inspection of factories to ensure compliance with the Act’s provisions.

- To impose penalties for non-compliance to deter errant employers.

Defining a “Factory”: The Scope and Applicability of the Act

The applicability of the Factories Act hinges on the definition of a “factory” and a “manufacturing process.”

What constitutes a “factory”?

Under Section 2(m) of the Act, a “factory” is any premises, including its precincts, where:

- With the aid of power: Ten or more workers are employed, or were employed on any day of the preceding twelve months, in a manufacturing process.

- Without the aid of power: Twenty or more workers are employed, or were employed on any day of the preceding twelve months, in a manufacturing process.

The definition explicitly excludes mines, mobile units of the armed forces, railway running sheds, and hotels, restaurants, or eating places.

What is a “manufacturing process”?

Section 2(k) of the Act provides a broad and inclusive definition of a “manufacturing process,” which covers a wide array of activities, including:

- Making, altering, repairing, ornamenting, finishing, packing, oiling, washing, cleaning, breaking up, demolishing, or otherwise treating or adapting any article or substance with a view to its use, sale, transport, delivery, or disposal.

- Pumping oil, water, sewage, or any other substance.

- Generating, transforming, or transmitting power.

- Composing types for printing, printing by letterpress, lithography, photogravure, or other similar processes, or bookbinding.

- Constructing, reconstructing, repairing, refitting, finishing, or breaking up ships or vessels.

- Preserving or storing any article in cold storage.

The judiciary has consistently interpreted these definitions broadly to extend the Act’s protections to a wide range of industrial activities.

The Pillars of Protection: Health, Safety, and Welfare Provisions

The core of the Factories Act is its detailed provisions concerning the health, safety, and welfare of workers. These provisions impose specific obligations on the occupier and manager of every factory.

Chapter III: Health of Workers

This chapter lays down stringent requirements to ensure a clean and hygienic working environment. Key provisions include:

- Cleanliness (Section 11): Every factory must be kept clean and free from effluvia arising from any drain, privy, or other nuisance. This includes the daily sweeping and cleaning of floors, the effective disposal of dirt and refuse, and the regular painting or varnishing of walls and ceilings.

- Disposal of Wastes and Effluents (Section 12): Effective arrangements must be made for the treatment of wastes and effluents due to the manufacturing process carried on in the factory to render them innocuous and for their disposal.

- Ventilation and Temperature (Section 13): Every workroom must have adequate ventilation by the circulation of fresh air and a comfortable temperature must be maintained.

- Dust and Fume (Section 14): In factories where dust, fume, or other impurities of such a nature and to such an extent as is likely to be injurious or offensive to the workers are given off, effective measures must be taken to prevent their inhalation and accumulation in any workroom.

- Artificial Humidification (Section 15): The Act regulates the methods used for artificially increasing the humidity of the air and prescribes standards of humidification.

- Overcrowding (Section 16): To prevent overcrowding, the Act specifies a minimum of 14.2 cubic metres of space for every worker in factories built after the commencement of the Act.

- Lighting (Section 17): Factories must be provided with sufficient and suitable lighting, both natural and artificial.

- Drinking Water (Section 18): An adequate supply of wholesome drinking water must be provided and maintained at suitable points conveniently situated for all workers. In factories employing more than 250 workers, arrangements for cool drinking water must be made during hot weather.

- Latrines and Urinals (Section 19): Sufficient latrine and urinal accommodation of prescribed types must be provided conveniently situated and accessible to workers at all times while they are at the factory. Separate enclosed accommodation must be provided for male and female workers.

- Spittoons (Section 20): A sufficient number of spittoons must be provided in convenient places and they must be maintained in a clean and hygienic condition.

Chapter IV: Safety of Workers

This chapter is dedicated to preventing accidents and ensuring the physical safety of workers. Its comprehensive provisions cover a wide range of potential hazards:

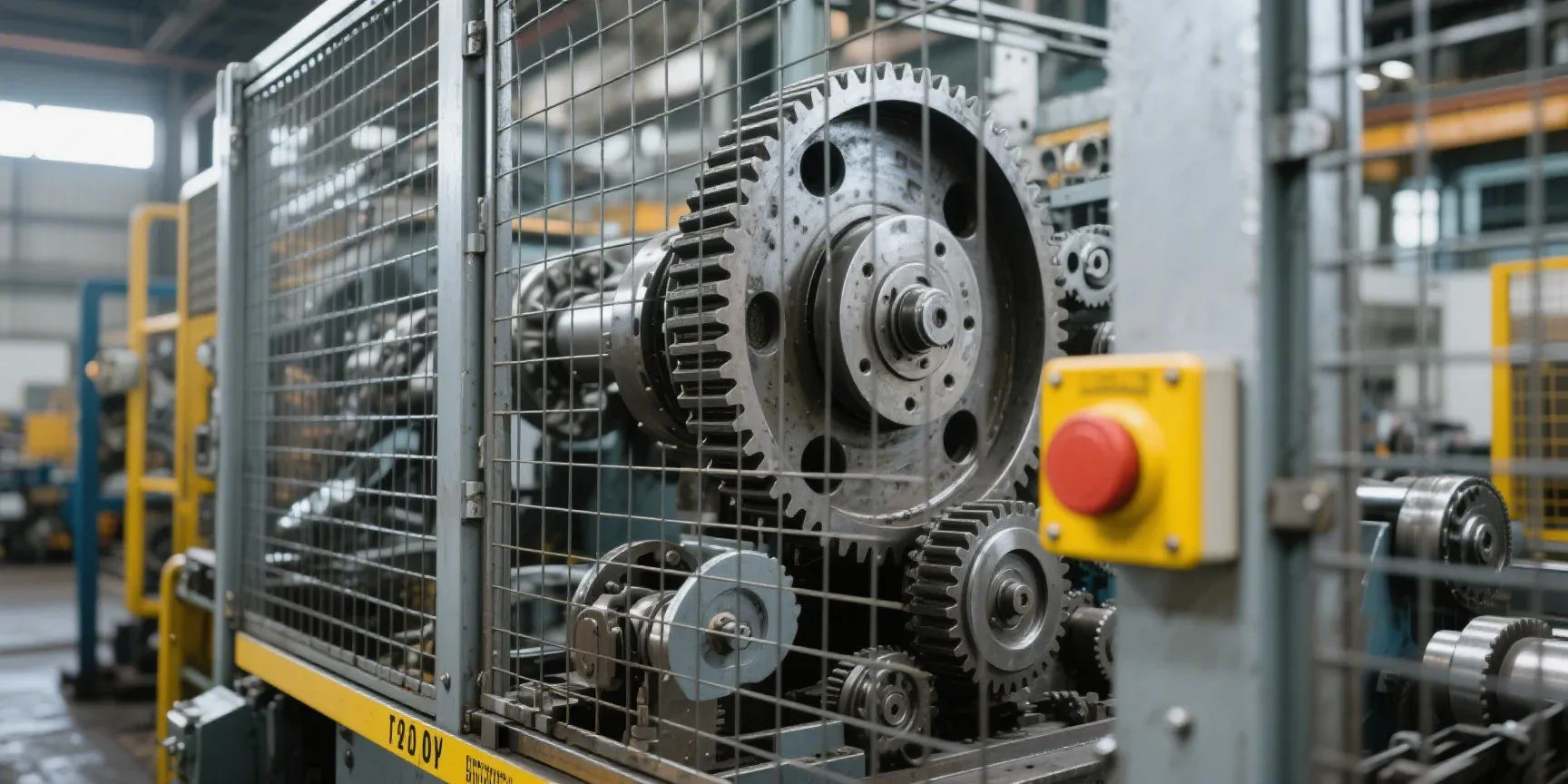

- Fencing of Machinery (Section 21): All dangerous parts of machinery must be securely fenced. This includes every moving part of a prime mover and every flywheel connected to a prime mover, the headrace and tailrace of every water-wheel and water-turbine, and every part of an electric generator, a motor or a rotary converter.

- Work on or near Machinery in Motion (Section 22): The Act lays down strict conditions under which examination or lubrication of machinery in motion can be carried out, and only by specially trained adult male workers.

- Employment of Young Persons on Dangerous Machines (Section 23): No young person shall be required or allowed to work at any machine to which this section applies, unless he has been fully instructed as to the dangers arising in connection with the machine and the precautions to be observed, and has received sufficient training in work at the machine, or is under adequate supervision by a person who has a thorough knowledge and experience of the machine.

- Striking Gear and Devices for Cutting off Power (Section 24): In every factory, suitable striking gear or other efficient mechanical appliances must be provided and maintained and used to move driving belts to and from fast and loose pulleys which form part of the transmission machinery, and such gear or appliances must be so constructed, placed and maintained as to prevent the belt from creeping back on to the fast pulley.

- Self-acting Machines (Section 25): The Act restricts the space within which any person is allowed to pass between fixed and moving parts of self-acting machinery.

- Casing of New Machinery (Section 26): All machinery driven by power and installed in any factory after the commencement of the Act must be so sunk, encased, or otherwise effectively guarded as to prevent danger.

- Prohibition of Employment of Women and Children near Cotton-openers (Section 27): Women and children are prohibited from being employed in any part of a factory for pressing cotton in which a cotton-opener is at work.

- Hoists and Lifts (Section 28) and Lifting Machines, Chains, Ropes and Lifting Tackles (Section 29): These sections mandate regular examination and maintenance of such equipment to ensure their safe operation.

- Revolving Machinery (Section 30): The Act prescribes the manner in which grinding on a revolving wheel or other machinery must be conducted.

- Pressure Plant (Section 31): Where any operation is carried on at a pressure greater than atmospheric pressure, effective measures must be taken to ensure that the safe working pressure is not exceeded.

- Floors, Stairs and Means of Access (Section 32): All floors, steps, stairs, passages, and gangways must be of sound construction and properly maintained and, where it is necessary to ensure safety, steps, stairs, passages and gangways shall be provided with substantial handrails.

- Pits, Sumps, Openings in Floors, etc. (Section 33): Every fixed vessel, sump, tank, pit or opening in the ground or in a floor which, by reason of its depth, situation, construction or contents, is or may be a source of danger, shall be either securely covered or securely fenced.

- Excessive Weights (Section 34): No person shall be employed in any factory to lift, carry or move any load so heavy as to be likely to cause him injury.

- Protection of Eyes (Section 35): The Act mandates the provision of suitable goggles or effective screens to protect the eyes of workers engaged in or in the vicinity of processes that involve a risk of injury to the eyes.

- Precautions against Dangerous Fumes, Gases, etc. (Section 36): No person shall be required or allowed to enter any chamber, tank, vat, pit, pipe, flue or other confined space in any factory in which any gas, fume, vapour or dust is likely to be present to such an extent as to involve risk to persons being overcome thereby, unless it is provided with a manhole of adequate size or other effective means of egress.

- Precautions regarding the use of portable electric light (Section 36A): In any factory, no portable electric light or any other electric appliance of voltage exceeding 24 volts shall be permitted for use inside any chamber, tank, vat, pit, pipe, flue or other confined space unless adequate safety devices are provided.

- Explosive or Inflammable Dust, Gas, etc. (Section 37): The Act prescribes measures to be taken where a manufacturing process produces any dust, gas, fume, or vapour of such a character and to such an extent as to be likely to explode on ignition.

- Precautions in case of Fire (Section 38): Every factory must be provided with such means of escape in case of fire as may be prescribed, and adequate and suitable fire-fighting equipment.

- Power to require specifications of defective parts or tests of stability (Section 39): If it appears to the Inspector that any building or part of a building or any part of the ways, machinery or plant in a factory is in such a condition that it may be dangerous to human life or safety, he may serve on the occupier or manager or both of the factory an order in writing requiring him before a specified date to furnish such drawings, specifications and other particulars as may be necessary to determine whether such building, ways, machinery or plant can be used with safety.

- Safety of buildings and machinery (Section 40): If it appears to the Inspector that any building or part of a building or any part of the ways, machinery or plant in a factory is in such a condition that it is dangerous to human life or safety, he may serve on the occupier or manager or both of the factory an order in writing specifying the measures which in his opinion should be adopted, and requiring them to be carried out before a specified date.

- Maintenance of Buildings (Section 40A): If it appears to the Inspector that any building or part of a building in a factory is in such a state of disrepair as is likely to lead to conditions detrimental to the health and welfare of the workers, he may serve on the occupier or manager or both of the factory an order in writing specifying the measures which in his opinion should be taken and requiring them to be carried out before such date as is specified in the order.

- Safety Officers (Section 40B): In every factory wherein one thousand or more workers are ordinarily employed, or wherein, in the opinion of the State Government, any manufacturing process or operation is carried on, which process or operation involves any risk of bodily injury, poisoning or disease, or any other hazard to health, to the persons employed in the factory, the occupier shall, if so required by the State Government by notification in the Official Gazette, employ such number of Safety Officers as may be specified in that notification.

Chapter IVA: Provisions relating to Hazardous Processes

Introduced by a 1987 amendment in the wake of the Bhopal Gas Tragedy, this chapter lays down stringent provisions for factories engaged in hazardous processes. It includes:

- Constitution of Site Appraisal Committees (Section 41A): For granting permission for the initial location of a factory involving a hazardous process.

- Compulsory disclosure of information by the occupier (Section 41B): The occupier must disclose all information regarding dangers, including health hazards, and the measures to overcome them.

- Specific responsibility of the occupier in relation to hazardous processes (Section 41C): The occupier has a special responsibility to maintain the health and safety of workers and to provide for the handling, storage, and transport of hazardous substances.

- Power of Central Government to appoint Inquiry Committee (Section 41D): The Central Government can appoint an inquiry committee to investigate the standards of health and safety in a factory engaged in a hazardous process.

- Emergency Standards (Section 41E): The Director-General of Factory Advice Service & Labour Institutes can lay down emergency standards for enforcement.

- Permissible limits of exposure of chemical and toxic substances (Section 41F): The maximum permissible threshold limits of exposure of chemical and toxic substances in manufacturing processes in any factory shall be of the value indicated in the Second Schedule.

- Right of workers to warn about imminent danger (Section 41H): Workers have the right to bring to the notice of the occupier, manager, and the Inspector, any apprehension of imminent danger.

Chapter V: Welfare of Workers

The Act also mandates several welfare measures to improve the working conditions and quality of life of workers:

- Washing Facilities (Section 42): In every factory, adequate and suitable facilities for washing shall be provided and maintained for the use of the workers therein. Separate and adequately screened facilities shall be provided for the use of male and female workers.

- Facilities for storing and drying clothing (Section 43): The State Government may, in respect of any factory or class or description of factories, make rules requiring the provision therein of suitable places for keeping clothing not worn during working hours and for the drying of wet clothing.

- Facilities for sitting (Section 44): In every factory, suitable arrangements for sitting shall be provided and maintained for all workers obliged to work in a standing position, in order that they may take advantage of any opportunities for rest which may occur in the course of their work.

- First-aid Appliances (Section 45): There shall in every factory be provided and maintained so as to be readily accessible during all working hours first-aid boxes or cupboards equipped with the prescribed contents, and the number of such boxes or cupboards to be provided and maintained shall not be less than one for every one hundred and fifty workers ordinarily employed at any one time in the factory. In factories employing more than 500 workers, an ambulance room must be provided.

- Canteens (Section 46): In any specified factory wherein more than two hundred and fifty workers are ordinarily employed, a canteen or canteens shall be provided and maintained by the occupier for the use of the workers.

- Shelters, Rest Rooms and Lunch Rooms (Section 47): In every factory wherein more than one hundred and fifty workers are ordinarily employed, adequate and suitable shelters or rest rooms and a suitable lunch room, with provision for drinking water, where workers can eat meals brought by them, shall be provided and maintained for the use of the workers.

- Crèches (Section 48): In every factory wherein more than thirty women workers are ordinarily employed, there shall be provided and maintained a suitable room or rooms for the use of children under the age of six years of such women.

- Welfare Officers (Section 49): In every factory wherein five hundred or more workers are ordinarily employed the occupier shall employ in the factory such number of welfare officers as may be prescribed.

Regulation of Working Hours: Ensuring a Work-Life Balance

The Factories Act, 1948, brought about a significant change in the regulation of working hours, a crucial aspect of preventing worker exploitation.

- Weekly Hours (Section 51): No adult worker shall be required or allowed to work in a factory for more than forty-eight hours in any week.

- Weekly Holidays (Section 52): Every worker is entitled to a holiday for a whole day in a week.

- Daily Hours (Section 54): No adult worker shall be required or allowed to work in a factory for more than nine hours in any day.

- Intervals for Rest (Section 55): The periods of work of adult workers in a factory each day shall be so fixed that no period shall exceed five hours and that no worker shall work for more than five hours before he has had an interval for rest of at least half an hour.

- Spreadover (Section 56): The periods of work of an adult worker in a factory shall be so arranged that inclusive of his intervals for rest under section 55, they shall not spread over more than ten and a half hours in any day.

- Overtime (Section 59): Where a worker works in a factory for more than nine hours in any day or for more than forty-eight hours in any week, he shall, in respect of overtime work, be entitled to wages at the rate of twice his ordinary rate of wages.

- Restrictions on Employment of Women (Section 66): No woman shall be required or allowed to work in any factory except between the hours of 6 a.m. and 7 p.m. However, the State Government may by notification in the Official Gazette, in respect of any factory or group or class or description of factories, vary the limits laid down in this clause, but so that no such variation shall authorize the employment of any woman between the hours of 10 p.m. and 5 a.m.

Protecting the Future: Provisions for Young Persons

The Act has special provisions for the employment of young persons, which includes both children and adolescents:

- Prohibition of employment of young children (Section 67): No child who has not completed his fourteenth year shall be required or allowed to work in any factory.

- Certificate of fitness (Section 69): A child who has completed his fourteenth year or an adolescent (a person who has completed his fifteenth year of age but has not completed his eighteenth year) cannot be employed in a factory unless a certificate of fitness granted by a certifying surgeon is in the custody of the manager of the factory.

- Working hours for children (Section 71): No child shall be employed or permitted to work in any factory for more than four and a half hours in any day and during the night. The period of work of all children employed in a factory shall be limited to two shifts which shall not overlap or spread over more than five hours each.

Annual Leave with Wages: A Right to Rest and Recuperation

Chapter VIII of the Act enshrines the right of workers to annual leave with wages, promoting their well-being and efficiency.

- Eligibility: Every worker who has worked for a period of 240 days or more in a factory during a calendar year is entitled to leave with wages in the subsequent year.

- Rate of Leave: For adults, leave is calculated at the rate of one day for every twenty days of work performed. For children, it is one day for every fifteen days of work.

- Wages during Leave Period: A worker is entitled to wages at a rate equal to the daily average of his total full-time earnings for the days on which he actually worked during the month immediately preceding his leave, exclusive of any overtime and bonus but inclusive of dearness allowance and the cash equivalent of the advantage accruing through the concessional sale to the worker of foodgrains and other articles.

The Role of the Occupier and Inspector

The Act places the primary responsibility for compliance on the occupier of the factory, who is defined as the person who has ultimate control over the affairs of the factory. In the case of a company, any one of the directors shall be deemed to be the occupier.

The Inspector, appointed by the State Government, is the key enforcement authority. The Inspector has wide-ranging powers, including:

- Entering any place which is used, or which he has reason to believe is used, as a factory.

- Making examinations of the premises, plant, machinery, and articles.

- Requiring the production of any prescribed register or any other document relating to the factory.

- Taking measurements and photographs and making such recordings as he considers necessary for the purpose of an examination under this Act.

Penalties for Contravention

Chapter X of the Act prescribes penalties for contravention of its provisions.

- General penalty for offences (Section 92): For any contravention of the provisions of the Act or of any rule made thereunder or of any order in writing given thereunder, the occupier and manager of the factory shall each be guilty of an offence and punishable with imprisonment for a term which may extend to two years or with a fine which may extend to one lakh rupees or with both, and if the contravention is continued after conviction, with a further fine which may extend to one thousand rupees for each day on which the contravention is so continued.

- Enhanced penalty after previous conviction (Section 94): If any person who has been convicted of any offence punishable under section 92 is again guilty of an offence involving a contravention of the same provision, he shall be punishable on a subsequent conviction with imprisonment for a term which may extend to three years or with a fine which shall not be less than ten thousand rupees but which may extend to two lakh rupees or with both.

Landmark Judicial Pronouncements

The judiciary has played a crucial role in interpreting and shaping the application of the Factories Act. Some of the landmark cases include:

- Ardeshir H. Bhiwandiwala v. State Of Bombay (Now Maharashtra) (1962): The Supreme Court held that the term “premises” is a generic term meaning open land or land with buildings or a building and that the process of converting sea water into salt amounts to a “manufacturing process.”

- Mohan Singh And Others v. Chairman, Railway Board And Others: The Supreme Court held that activities like repairing wagons, signals, and sanitation systems in a railway division constitute a “manufacturing process,” and the entire divisional area is considered “premises.”

- Indian Oil Corporation Limited v. Chief Inspector Of Factories And Others: The Supreme Court clarified the definition of “occupier,” emphasizing the concept of “ultimate control” over the affairs of the factory.

- Chinubhai Haridas v. State Of Bombay (1959): The Supreme Court interpreted the provisions relating to precautions against dangerous fumes, holding that the duty to provide breathing apparatus is absolute when entry into a confined space is permitted.

- Bhikusa Yamasa Kshatriya (P) Ltd. And Another v. Union Of India And Another: This case reiterated that for the Act to apply, there must be a manufacturing process, the requisite number of workers, and their employment must be in connection with the manufacturing process or the premises.

The Road Ahead: The Occupational Safety, Health and Working Conditions Code, 2020

In a significant move to reform India’s labour laws, the Central Government has enacted the Occupational Safety, Health and Working Conditions (OSH) Code, 2020. This Code subsumes 13 existing labour laws, including the Factories Act, 1948.

The OSH Code aims to simplify and modernize the legal framework, making it more responsive to the changing needs of the economy. While it retains many of the core principles of the Factories Act regarding health, safety, and welfare, it also introduces some key changes:

- Uniformity: The OSH Code provides for a uniform and comprehensive legal framework for all sectors, except for the armed forces.

- Broader Definition of “Establishment”: The Code has a wider definition of “establishment,” which includes any place where any industry, trade, business, manufacture, or occupation is carried on.

- National Occupational Safety and Health Advisory Board: The Code provides for the constitution of a National Occupational Safety and Health Advisory Board to advise the central government on matters relating to occupational safety and health.

- Flexibility in Working Hours: The Code provides for flexibility in the determination of working hours, with the consent of the workers.

- Single Registration: The Code provides for a single registration for an establishment instead of multiple registrations under different labour laws.

The implementation of the OSH Code is a work in progress, with the Central and State Governments in the process of framing the necessary rules. The transition from the Factories Act to the OSH Code will be a critical phase in the evolution of India’s labour jurisprudence.

Conclusion: A Legacy of Protection and a Future of Reform

The Factories Act, 1948, has been a bulwark of protection for India’s industrial workers for over seven decades. Its comprehensive provisions on health, safety, and welfare have significantly improved working conditions and have been instrumental in preventing exploitation. The judiciary, through its purposive interpretation of the Act, has consistently expanded its protective ambit.

As India moves towards a new era of labour law reform with the OSH Code, 2020, the foundational principles of the Factories Act will continue to be relevant. The challenge lies in ensuring a smooth transition and in effectively implementing the new Code to create a safer, healthier, and more humane working environment for all. The legacy of the Factories Act, 1948, is not just in its letter, but in the spirit of social justice and worker welfare that it embodies – a spirit that must continue to guide India’s industrial journey in the years to come.

Frequently Asked Questions (FAQ) about the Factories Act, 1948

Here are answers to some common questions regarding the Indian Factories Act, 1948, and its provisions.

1. What is the main purpose of the Factories Act, 1948?

The primary purpose of the Factories Act, 1948, is to consolidate and amend the law regulating labour in factories. Its core objectives are to ensure the health, safety, and welfare of workers, regulate their working hours, and provide for annual leave and other amenities to prevent exploitation and improve working conditions in India’s industrial sector.

2. When does a workplace become a “factory” under the Act?

A premises qualifies as a “factory” based on two main criteria: the number of workers and the use of power in a “manufacturing process.”

- With power: If 10 or more workers are engaged in a manufacturing process.

- Without power: If 20 or more workers are engaged in a manufacturing process. This includes the preceding twelve months, meaning if the worker threshold was met on even one day, the Act applies.

3. Does the Factories Act apply to small workshops or open-air sites?

Yes, potentially. The term “premises” is not limited to a building. As established in the Supreme Court case of Ardeshir H. Bhiwandiwala v. State of Bombay, it can include open land. Therefore, operations like salt works, construction sites, or shipyards can fall under the Act’s purview if they meet the criteria for a “manufacturing process” and the required number of workers.

4. Who is considered the “Occupier” and what are their main responsibilities?

The “Occupier” is the person who has ultimate control over the affairs of the factory. In a company, any one of the directors can be designated as the occupier. The Occupier is primarily responsible for ensuring compliance with all provisions of the Act, including the health, safety, and welfare of all workers on the premises. They are the primary individual held liable in case of any contravention.

5. What are the standard working hours for an adult worker in a factory?

An adult worker cannot be required or allowed to work for:

- More than 48 hours in any week.

- More than 9 hours in any day. Additionally, they are entitled to a weekly holiday and must be given a rest interval of at least 30 minutes after a maximum of 5 hours of continuous work. The total spread of the workday, including rest intervals, cannot exceed 10.5 hours.

6. Are there special provisions for women workers?

Yes. The Act places restrictions on the employment of women to ensure their safety and well-being. Generally, women are not permitted to work in a factory between 7 P.M. and 6 A.M. State governments can grant exemptions, but employment between 10 P.M. and 5 A.M. is prohibited under most circumstances. The Act also mandates amenities like separate washing facilities and crèches in factories employing a certain number of women.

7. Is child labour permitted under the Factories Act?

No. The Act strictly prohibits the employment of any child who has not completed their 14th year in any factory. “Adolescents” (those between 15 and 18 years) can only be employed after obtaining a certificate of fitness from a certifying surgeon and are subject to specific restrictions on their working hours.

8. What is the penalty for not complying with the Factories Act?

Non-compliance with the Act is a serious offence. Under Section 92, both the Occupier and the Manager can be held liable. Penalties can include imprisonment for up to two years, a fine of up to ₹1,00,000, or both. For repeated offences, the penalties are more severe. In cases involving hazardous processes or resulting in death or serious injury, the penalties are significantly enhanced.

9. What are the key welfare facilities that a factory must provide?

The required welfare amenities depend on the number of workers employed. Key provisions include:

- Adequate washing facilities.

- First-aid boxes (and an ambulance room for factories with over 500 workers).

- Canteens (for factories with over 250 workers).

- Shelters, rest rooms, and lunch rooms (for factories with over 150 workers).

- Crèches for children under six (for factories with over 30 women workers).

- Appointment of a Welfare Officer (for factories with 500 or more workers).

10. Is the Factories Act, 1948, still in effect? What is the new OSH Code?

The Factories Act, 1948, is still in effect as of mid-2025 because the central government has not yet notified the date for the implementation of the new labour codes that will replace it. The Occupational Safety, Health and Working Conditions (OSH) Code, 2020, is a new piece of legislation that will subsume and replace the Factories Act along with 12 other related laws. The OSH Code aims to simplify and modernize the legal framework, expanding its coverage to more establishments. Once its implementation is officially notified, it will become the primary law governing workplace safety and health in India.